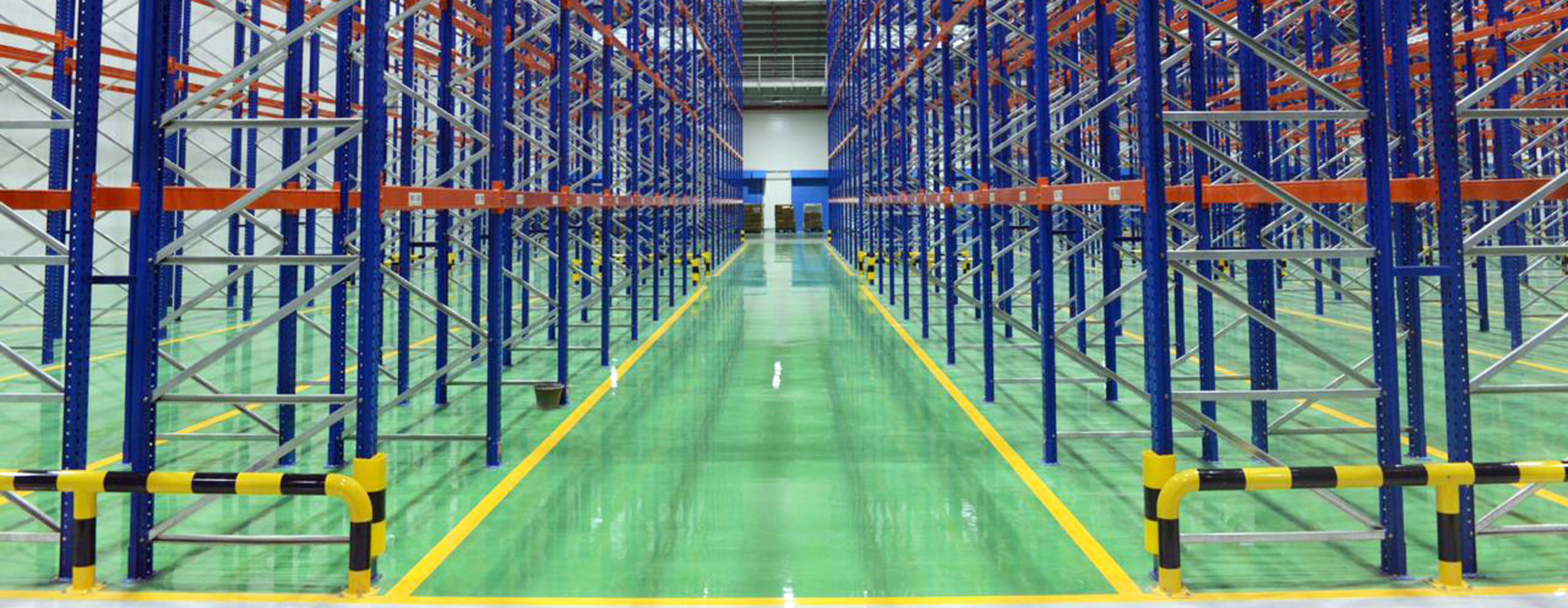

Flat Floor Construction

What Is a Superflat Floor?

A superflat floor is built to a much tighter tolerance than a normal floor slab, using a special tolerance system called the Fmin tolerance system. This is based on defining a floor’s maximum variation for a certain lift truck. The optimization of a surface provides multiple benefits — it optimizes the lift truck’s performance, reduces maintenance-related costs and eliminates the chance of picking problems, which include rack impact.

Builders are able to control highly accurate longitudinal and transverse tolerances by using specialized methods, materials and formwork to pour the concrete in narrow strips. Contractors must keep the following in mind when they specify and design superflat floors:

- It is mandatory to strip pour: Strip pouring techniques are absolutely required for high-rack, narrow-aisle environments where AGVs, or automatic guided vehicles, are used. Otherwise, it is extremely difficult to achieve these demanding transverse and longitudinal tolerances.

- Superflat floors must not have transverse saw cuts: Shrinkage and curling can occur at contraction joints that are transverse, which can lead to tolerance losses and make superflat floors completely unusable.

- Floor tolerances need to be measured every day: This must be done with highly sensitive profilograph equipment. If the tolerances are not measured daily, then any construction defects will unnecessarily worsen. If a floor is not measured, then its surface quality cannot be certified. We’ll examine profilograph equipment in greater detail below.

- Fmin tolerances only apply to floors with defined traffic: The FF/FL F-number tolerance system is used for surfaces with random traffic, not defined traffic. The FF/FL system doesn’t address the transverse and longitudinal equipment tolerances.

- Make sure that the continuous steel embedded in the concrete is positioned correctly: Its location shouldn’t disrupt the guidewire electrical signals. Steel fibers have proven not to do this. They’re also durable, economical and versatile in that they can address a wide variety of user needs.

- Some dry-shake hardeners may not work: Certain dry-shake hardeners could prevent you from achieving superflat tolerances. Commonly used surface solutions depend on a concrete mix that is reduced-wear with a 0.50 w/c maximum and a densifier that is liquid. For the liquid densifier, the right product will depend on the environment and require much careful consideration.

GOLDEN TROWEL ASIA

|

|

PT Multibrata Anugerah Utama, also known as “MAU” is the first company from Indonesia to win a Golden Trowel Asia award for their 253,000 ft2 Copperhead-on-elevated-piles project in Cikarang, Indonesia that measured FF 57 / FL 42.2.